Make your 2X MATCHED gift today!

This week only: Every $1 will be matched with $2 to enable women worldwide.

This week only: Every $1 will be matched with $2 to enable women worldwide.

Posted on 09/04/2025

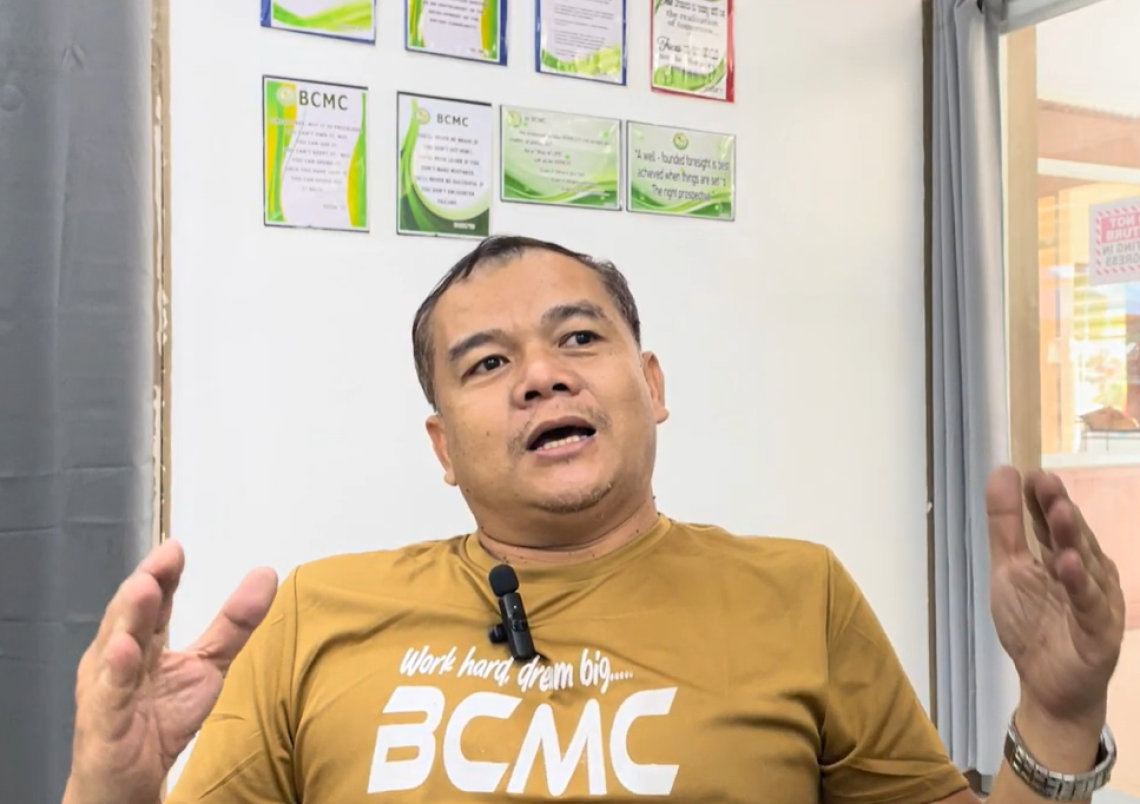

(Davao, Philippines). Reynante Madelo, Marketing Head and Loan Officer of Bansalan Coconut Farmers and Workers Multi-purpose Cooperative (BCMC), witnessed his cooperative’s growth over the past three years and was eager to discuss it with me. BCMC was once struggling with low income, limited market access, and minimal member engagement, but it has evolved into a more organized, profitable, and farmer-driven operation. Through Grameen’s new curriculum and training on improving copra quality standards, and by building stronger relationships with buyers and farmers, the cooperative has not only increased its trading capacity but regained the trust and active participation of its members.

Grameen has been partnering with BCMC and 11 other copra cooperatives for the past three years through the sustainable coconut project (SCP). SCP aims to strengthen Barry Callebaut’s sustainable coconut oil value chain to impact Davao-based smallholder farmer copra (dried coconut meat) suppliers. SCP is implemented by Grameen Foundation, working directly with coconut cooperatives and partner oil mills. Prior to SCP, BCMC (and other cooperatives) faced lower volumes of trade, and as a result, limited smallholder farmer engagement.

Tailored Training on Copra Quality led to Cooperative Efficiencies

During the pandemic, BCMC was operating with a skeletal workforce and staff were only working two days a week. “Before the project, [and during the COVID pandemic] we barely reached 100 tons of copra per month,” Reynante explained.

Between 2021 and 2022, warehouse volumes increased slightly and reached 300MT, but their turnover remained low due to poor quality copra resulting in significant deductions at oil mills. By providing tailored training for farmer suppliers through extension officers, the farmers’ standard individual drying practices improved and copra moisture content reduced. At the time of the SCP baseline (2021), the cooperative was curing (air drying their copra), before selling to oil mills, and the average moisture content of BCMC copra was at 11%. Now, to prioritize cost-effectiveness and efficiency, Reyante has halted curing on the cooperative level, moving copra out of the cooperative’s warehouses faster than before to take into consideration the higher copra prices (stemming from the global markets). Considering the improvement amongst farmers’ harvest and drying practices, the moisture content has remained at 11%, and BCMC has saved on curing-related labor costs and time with quicker trades with the oil mill.

Reynante noted how the training shifted the behavior of the coconut farmers. Before the training, both farmers and the cooperative lacked technical awareness about copra quality and moisture content. Some farmers would sell rubbery or wet copra to the cooperative, even deliberately re-wetting dried copra to earn immediate income. Wet or re-wetted copra weighs more, and if buyers don’t enforce strict moisture testing, farmers can earn more per delivery. With the SCP’s training priority on quality copra, farmers began producing higher-quality copra. According to Reynante, farmers are now actively selling improved quality copra to the cooperative – copra that is better dried, mold-free, whiter in color, processed from mature coconuts, sun-dried in a clean environment, and properly stored in well-ventilated, shaded areas. This change has led the cooperative to maximize efficiencies and sell more and trade more often with the oil mill to take advantage of the high copra market prices.

Three training modules were specifically designed by the SCP for copra smallholder coconut farmers in Davao, and were used to train cooperative-member and non-member smallholder farmers alike. At least 2,250 farmers have been trained on 1) copra quality enhancement, 2) improving coconut productivity and income, and 3) integrating other enterprises in coconut farming. The process of developing the materials was a deliberate, concentrated set of efforts: A landscape review of training implemented by other organizations and a training needs analysis were done to finally come up with these three modules so as to not ‘reinvent the wheel’, an important Grameen Foundation value. An expert on coconut production and quality from the University of the Philippines was engaged to support.

Technical Assistance for the Cooperative

The SCP provided tailored technical assistance to BCMC through Grameen Foundation’s expert-volunteer-program called: Bankers Without Borders (BwB).

Internally, the cooperative has matured. Reynante reflected on previous challenges involving conflicts that would arise amongst board members, hindering progress. At one point the conflicts halted moving forward on a BwB initiative led by volunteer Solitario Discar Jr that would have guided BCMC on enhancing its policies to further facilitate copra trading growth. “It was a well- prepared proposal that could’ve really helped us,” he said. “It’s time we reintroduce it, especially now that our board and employees are united and working as one team."

Securing Trust with Partner Oil Mills

BCMC joined the SCP in 2023, during which time the project facilitated a gain-sharing system between engaged partner cooperatives and partner oil mills. Through dedicated consultations and negotiations which took into consideration cooperative requirements and mill-related mandates, the partner oil mills implemented priority opportunities for SCP partner cooperatives. This included priority delivery lanes so that the cooperatives would not be stuck waiting outside the mill to deliver their copra for days. Pleased with these special opportunities, cooperatives began delivering up to 80% of their volume to partner oil mills. At present, BCMC delivers up to seven truckloads per delivery compared to the previous two. The mills took it upon themselves to further establish their trust-based relationship with cooperatives by providing cash advances, enabling cooperatives to solidify their trading partnerships with the mills.

The SCP provided partner cooperatives, including BCMC, the opportunity to trace and document their copra volume all the way down to their farmer suppliers (by leveraging Grameen’s Farmerlink traceability platform). This also further facilitated shorter delivery waiting times at the mills by prioritizing the partner cooperatives, and also aided in securing competitive prices with the mills.

As a result of their engagement with SCP, Reynante sees a strong future for BCMC, increasing profits through higher volumes of copra trading through more deliberate interventions to maintain relationships with farmer suppliers and partner oil mills. He believes this growth will be rooted in providing value and continued training opportunities for their increasing membership base. “Our purpose is to grow,” he shared. “And one way to do that is through the collective support of members and non-members by educating and encouraging them to sell their products through BCMC.” He remains hopeful that with continued support from the SCP and Grameen, BCMC can reach even greater heights.