Make your 2X MATCHED gift today!

This week only: Every $1 will be matched with $2 to enable women worldwide.

This week only: Every $1 will be matched with $2 to enable women worldwide.

Posted on 05/30/2023

I recently had the opportunity to go to the Philippines. I was invited by Grameen Foundation to work with a cocoa and chocolate production Cooperative in Maragusan, Philippines. The goal of the project was to work on their fermentation with the hopes to improve their chocolate.

Getting There

The trip to Maragusan is pretty long. First from Detroit to Manila with a layover in Seoul. We lost 12 hours so I was very surprised to see the sun rise in Seoul. We spent one night in Manila and then another flight to Davao then a 2-3 hours drive to Maragusan in the pouring rain.

Luckily it was the tail end of the rainy season and the rest of the time there was pretty pleasant weather-wise. Especially after hearing about ice storms and power outages in Michigan, I was happy to be there. Maragusan is in the mountains just enough to be a perfect temperature. Sea level in the Philippines is very hot.

Maragusan is a small city, Population 64,000. As you would expect on a nation of islands, there was lots of fresh seafood and tropical fruits. The place I stayed was overlooking Maragusan and we had to take a cable car to get up to the hotel. The power was out a few times and we has to walk up which was a little taxing but doable.

We opened my two weeks in Maragusan with a meeting of local officials, representatives from Grameen Foundation and some of the employees of the cooperative MAMPCO and I spoke a little about how I planned to approach the project and that I would come up with some recommendations. Overall I was very well received and appreciated for coming to help. My challenge surfaced during Q&A when one person who was reluctant to believe that I could offer any suggestions that could improve their chocolate. I think some of them believed their chocolate was already the best!

I visited the MAMCO cooperative processing station where the cocoa is brought from the farms to be fermented, dried, roasted made into chocolate.

I saw several opportunities for improvement right away. From selecting the variety of cocoa to tempering and storing the chocolate. So we started to work right away.

I saw a few areas for improvement. Fresh banana leaves on the fermentation boxes were my first suggestion. We found a way to get them to the coop on a regular schedule so they are always fresh. Honestly I don’t know if rotting banana leaves will hurt fermentation but I have only seen fresh leaves on fermentation boxes and it just seems like a good idea.

Second we talked about a faster way to transfer the beans from fermentation box to box. I was concerned that the method they were using which was transferring the beans scoop by scoop and the temperature of the fermentation would have a chance to come down too low.

We looked at some cut tests of cocoa beans and talked about what to look for in beans, fermenting them fully and what effect the big range of bean sizes could have on flavor.

We looked at their drying beds and talked about how they manage during the rainy season so the beans have a better chance of drying and less chance of molding. If they do mold or rot? “that’s ok, they can sell those beans to companies that only care about price not quality. Mars is one of their customers.

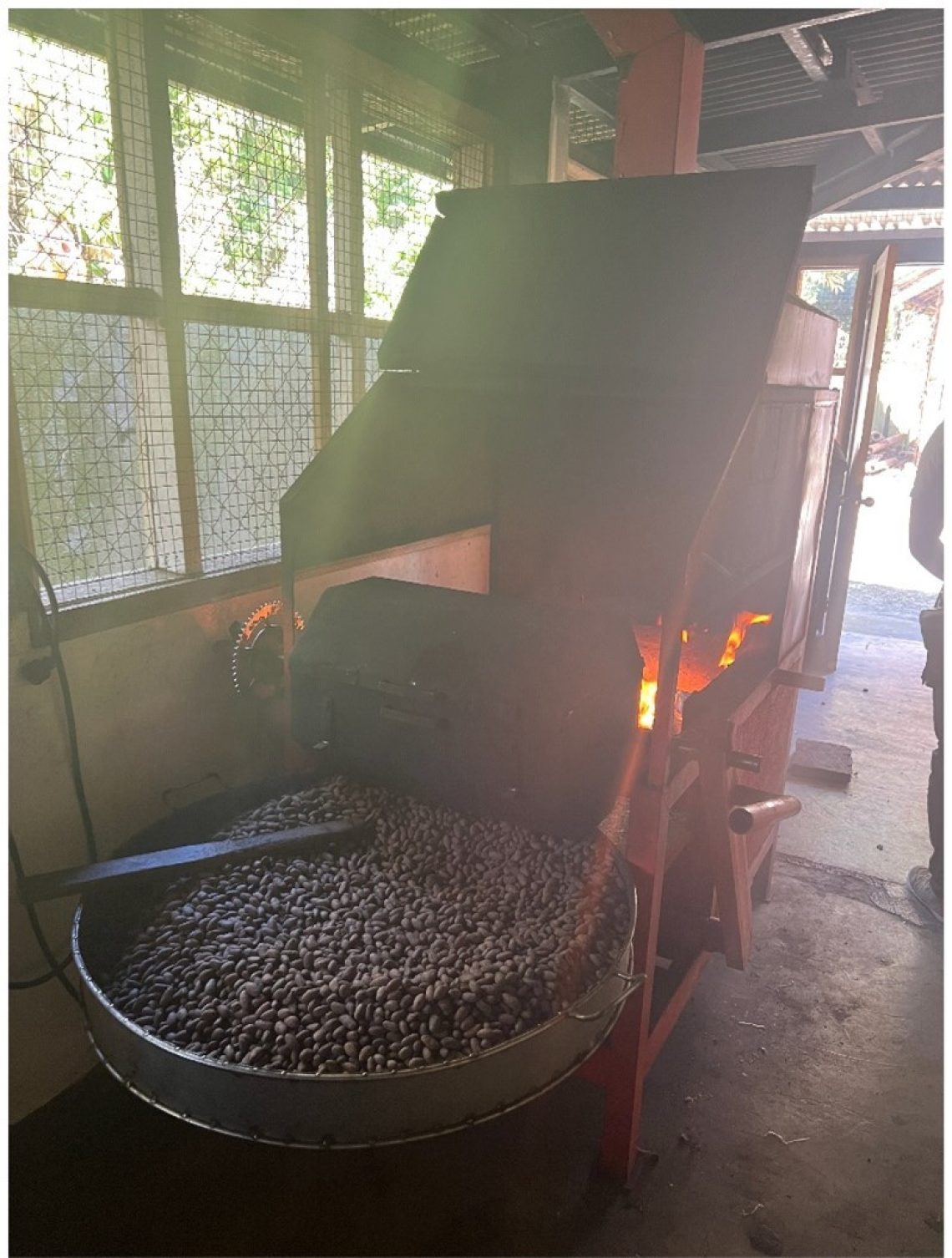

Next on to the roasting. I was so excited to see that they are using a wood burning roaster. There is no smoke taste in their chocolate which was my first concern. I suggested that we try a few roasts that are at a lower temperature and longer roasts to see if that will improve the flavor. I prefer the complex flavors that we get when cocoa beans are roasted more lightly. The production staff was very excited at how much better the roasted beans tasted when they were roasted at a lower temperature.

We took a look at the chocolate production kitchen. They are grinding the roasted cocoa nibs in a grinder that gets very hot while grinding. I suggested that they slow the grinder to run a slower grind and won’t heat the beans so much while grinding. We did not have a thermometer that worked but the cocoa mass (ground cocoa beans) was very, very hot.

Next we took a look at the tempering and production processes. We decided to revisit tempering. As of this time they were not tempering their Tablea (blocks of drinking chocolate) and I think if they want to appeal to a larger audience the chocolate will need to be pretty. The means it must be in temper and shiny.

Next we did a tasting of their “new” lighter roasted chocolate and compared Mindo chocolate with MAMPCO’S.

We took a trip to a few cocoa farms that belong to the cooperative. We talked about the variety of cocoa and exactly what our goal for the project is.

The goal for cocoa on the vast majority of cocoa farms has focused and still focuses mostly on high production, easy to harvest beans and on disease resistance. Larger pods, larger beans, short trees that produce a lot of cocoa.

But our goal here is delicious and award winning chocolate. And to get that we need a new strategy. We talked about selecting the best tasting variety cocoa and isolating it from other varieties. This goes completely against what they learned in Ag school and against what they are told to do.

They all already knew which variety tastes best and we tasted the fruit of the variety that they like best and compared it to a second variety. The fruit of the better tasting cacao was complex, fruity, sweet and delicious. The second one was metallic and plain tasting. I was surprised at the big difference in taste.

My Final Report

At our last meeting I reported on my findings and my suggestions for things that they could do to improve the flavor of their chocolate. We had samples of the cocoa beans and the new chocolate roasted at a lower temperature and compared it to the chocolate the way they were roasting the beans before I got there.

It was obvious which chocolate they liked better as the new chocolate disappeared completely within minutes. It was really rewarding to see their surprise and excitement when they tasted the new chocolate.

The last bit of the meeting was a recap of my time there.

The most rewarding part was the person who was at the first meeting, the one who who questioned my ability to make any improvements spoke.

He said again the he hadn’t thought we could improve the taste of the chocolate. But he said that he was wrong and that the project was a success. The chocolate did taste better!

They still have many areas where they could see vast improvements, but having another success will open up those who are hesitant to new ideas and to making changes which it always hard.

Other fun stuff that I did in the Philippines:

I ate durian for the first time. I am not a fan. I tastes like it smells...don't let them fool you. I had some cool new experiences like visiting the amazing hot springs, riding on trikes, eating some amazing food, and making lots of new friends.

See more photos from the trip below: